How To Install Water Underfloor Heating

Water Underfloor Heaing – DIY Guide Looking at How to Install Water Underfloor Heating and the Different Systems Available Including Laying on Existing Flooring Types

In this DIY project find Data and facts on h2o underfloor heating, how the dissimilar heating systems piece of work, what flooring types information technology can be laid on such every bit solid concrete floors, screeded concrete floors and timber floors, what unlike types of zone setup are available including single zone underfloor heating systems and multi zoned systems, how mixing manifolds are used to command temperatures and how it is installed in a property.

H2o underfloor heating or underfloor hot water heating as it'southward sometimes known is suitable for all types of property, whether domestic or commercial, and information technology can be easily linked into whatever rut source including solar, and also geothermal heating systems, or even an existing or new central heating system.

Underfloor heating has plenty of benefits compared with the more conventional radiators that we've all been used to and it is suitable for all types of property. It's possible to rut a small-scale conservatory, kitchen or bath or heat the whole house in this manor.

There are many companies out there that supply and fit underfloor heating systems. Nigh companies volition supply all the elements necessary to install in your habitation along with a qualified fitter to behave out the work for you lot. Some companies as well offer DIY kits then that y'all can install your self.

How Water Underfloor Heating works

Underfloor heating uses radiant heat. This ensures that you feel comfortable even at a lower air temperature than that produced by a more than conventional, convection heating organisation (wall mounted radiators). With underfloor heating, the whole floor is heated. This means that no matter where you are in the room it's all at an even temperature.

Water underfloor heating comes in the form of a series of piping loops that are laid underneath a surface (tiles, laminate floor etc….). This then effectively turns your floor into a giant radiator!

The pipework to run the arrangement is connected to your existing heating system via a manifold. The manifold is normally located in an like shooting fish in a barrel to access position in instance maintenance or repair is required.

Instead of high temperature water existence required (as in wall mounted radiators) lower temperature water tin can exist used (normally around 50°C) due to the fact that the heating surface is much bigger and unlike a conventional heat source (wall mounted radiators) information technology does not need to requite off as much heat per sqm in order to heat a given space to a required temperature. This has quite a few benefits in that the banality then becomes much more efficient equally it does not need to heat the h2o as much and in turn becomes cheaper to run and is kinder to the environment.

Another benefit of underfloor heating is that there is nil to show around the abode except the room thermostat. At that place are no radiators to decorate and no difficult decisions on where to put your article of furniture and so that it doesn't get ruined in forepart of a radiator, This gives y'all complete design freedom. It is also an ideal solution for areas with high ceilings.

There are quite a few dissimilar options and situations to expect at if you are considering underfloor heating, with some being more than suited to sure situations/needs than others. Below yous will find a option of the most mutual setups:

The Different H2o Underfloor Heating Setup's

Single Zone Underfloor Heating System

Warm water is circulated from the boiler to a zone valve which is operated electrically and treated equally one zone (typically in this setup this will include whatever room that features underfloor heating that is all connected to the same system due east.m. yous could have UFH in your living room, kitchen and dinning room all on the aforementioned loop and this will be treated as one zone)

If you currently take a combination boiler running your heating organization you lot will also need to zone your radiators in order to achieve the all-time possible operating scenario

If, however, you have a banality that also runs and heats a hot water cylinder these should already be zoned (1 zone for hot h2o and 1 zone for radiators). If this is the case you lot volition only need to add the UFH (underfloor heating) manifold separately with a zone valve which volition make your arrangement a iii zone system.

In this scenario, when yous activate the heating (or your programmable room thermostat turns the heating on) h2o will laissez passer through the organisation and heat the given floor surface area

Multi Zoned Underfloor Heating System

A multi-zoned system works in a very like manner to a single zone organization but the departure comes in the fact that in that location is no demand for a zone valve for your underfloor heating system. All the same y'all volition need to zone your hot water cylinder and radiators.

In identify of the zone valve in that location would feature a wiring middle that would then independently provide control to underfloor system separately from your radiators and hot h2o arrangement

In this situation, your programmable thermostat/fourth dimension clock will activate all of the underfloor heating thermostats and then private rooms tin then exist controlled via a programmable room thermostat – in essence you lot will so have the power to command the temperature and starting time of heating in any room with the feature. When a thermostat is turned on, an electronic valve that is fitted to the acme body of the manifold opens and in turn will also actuate your pump and burn up your banality.

Every loop on the manifold is then capable of independent command which as you may have guessed ways typically 1 loop per room (just this can sometimes depend on the size of the room)

Mixing Manifold

Hot water supplied past your boiler is passed through an actuator head (valve) and then passed on into the underfloor heating manifold which and so in turn draws water from the underfloor heating pipework. When this happens the cold water that is in the underfloor heating pipework is and so mixed with the hot water from the boiler and is then passed through the pump and so over a temperature sensor.

If the water passing over the temperature sensor is detected as being warmer than the temperature that has been set up by the sensor (usually somewhere between 20 and 65 degrees), the zone valve volition shut and too turn off the boiler.

Process for Installing H2o Underfloor Heating

About domestic underfloor systems are designed to be very unproblematic in nature and in turn should be quick and relatively elementary to install. Due to this the skill level involved in plumbing fixtures should as well exist less and thus it makes a great DIY project!!

Pretty much every system should be compatible with all existing conventional heating systems / boilers / radiators etc…. (Please cheque before purchase) and they should also exist compatible with all know flooring and floor covering types you would expect to find in a home (Once more, please check your flooring types and confirm with your supplier before purchase). Systems should besides be compatible with geo-thermal and solar heating systems.

Every underfloor heating arrangement supplied should come very details installation instructions and likewise information on how to commission your system once it has been installed (e.g. priming and filling the organization etc….).

If you accept chosen to become downwardly the DIY route and install the nether floor pipe work yourself and you too have some knowledge of heating systems, once the pipe work is laid you tin then connect into your existing heating system into the underfloor system manifold. All y'all should require in lodge to achieve this are some standard fittings. If you accept laid the pipe work but do not feel confident enough to connect into your heating system then you will need to call a plumber in. This should not take him any more than a few hours to complete.

Typical Water Underfloor Heating Manifold

Over again if you feel confident plenty, once the plumber has completed the connection process you can and so make full, bleed and balance the system yourself, if non y'all may wish to ask the plumber to do this for you while he is there

With all the pipe work laid and continued into your arrangement you will now need to connect the electrical side of things e.g. thermostats etc…. If yous have any programmable controllers or zone valves, the underfloor heating organization will exist connected into these forth with your boiler and then that you will then take command via your existing heating setup of the new underfloor system

The electrical connections are all made at the manifold controller, which is placed above the manifold. It is here that your electrician volition demand to wire the thermostats, using standard 3 core & world cable. This will then link to your boiler and too whatever programmable controllers and zone valves.

The essence of most underfloor heating systems is simplicity and compatibility. The system should be easy to install and all parts involved in its construction and connection should be available from your local plumber's merchants

What Existing Flooring Types can I lay Underfloor Heating on Top of?

Water underfloor heating can be laid on a dandy deal on floor surfaces that cover pretty much every scenario you would find in your home. Beneath y'all volition find a listing of typical surfaces and a brief clarification of what is involved in laying your heating:

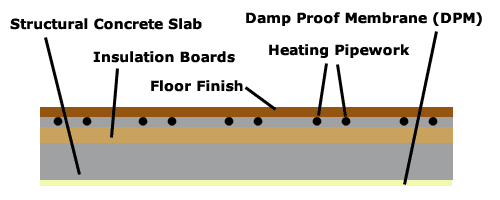

Solid Screeded Floor

This is quite a straight forward task as much of the piece of work involved in laying the heating pipes will already exist completed. Essentially the heating, insulation and screed are laid on top of your structural concrete slab (if yous already have ane, y'all may demand to check)

Firstly you lot will need to lay downwardly your DPM (Damp Proof Membrane). Once this chore has been completed a layer of concrete will need to exist added on top of the DPM to create your structural slab, ensure that this is level and flat.

One time the slab has cured correctly you will then take to lay insulating boards on top on the slab (check with your local edifice control department for the exact requirements for insulation). Over again every bit in examples to a higher place, this will need to be rigid.

Once the insulation has been added you then need to lay the underfloor h2o heating pipework on top of the insulation and fix using clips.

With the insulation in identify and the pipework fixed to it you can then lay your screed on top ensuring that it is apartment and level. One time this screed has cured correctly, you can and then lay your desired flooring on top.

Underfloor Water Heating Pipework Laid in Screed Flooring

Solid Concrete Floor

This is a similar method to the one outlined higher up with the only difference being that the water underfloor heating pipe piece of work is laid inside the concrete slab.

The basis of this method is that, firstly, the DPM is laid on a base and then the insulation boards are laid on superlative of the DPM (cheque with your local edifice command department for the verbal requirements for insulation). The underfloor heating pipework is then laid on top of the insulation boards and fixed to the boards.

Once this has been done the physical slab is poured on elevation of the insulation and pipework and levelled off to give a solid concrete flooring surface

Every bit you may have guessed the main departure between this method and the one above is that just one layer of concrete is poured as opposed to a physical slab layer and a screed layer outlined in the method above

Already Insulated Concrete Floor

If your existing physical slab already features an insulation layer, the task of laying your underfloor heating is some what simplified a footling.

In this instance you lot would need to lay a series of 25mm timber battens over the superlative of the physical surface (at 400mm centres).

Once this has been done you can and then lay your heating pipework in between the battens and fix to the concrete slab using the appropriate clips.

With the pipework laid the final task is to screed over the acme of the pipework up to and level with the top of the batten. Once the screed is correctly cured you can then go ahead and lay chipboard over the peak

United nations-Insulated Concrete Floor

If you are laying on top of an un-insulated concrete floor base you will need to firstly lay a serial of 76mm x 50mm (3" by 2") timber joists across the surface of the concrete base of operations at 400mm centres and then lay insulation boards between the joists, ensuring a tight fit with no gaps (check with your local edifice control department for the exact requirements for insulation).

All underfloor heating pipework is and so laid on summit of the insulation so screed is added and filled up to the level of the meridian of the joist.

In one case the screed has cured correctly chipboard flooring is laid over the top and your desired flooring selection e.chiliad. laminate on elevation of this.

Pipework Laid in Screed on pinnacle of Concrete Floor

In some instance yous may detect that your base of operations already has insulation added on height of the DPM with a concrete slab laid over the acme of this.

If this is the case and then the pipework for your underfloor heating organization is laid and fixed directly on elevation of the concrete base and then a screed is poured over this (normally this will be a 75mm screed).

Once the screed has cured you tin can and so go ahead and lay your desired flooring on top of the screed.

Heating Laid on Timber Flooring Using a Screed, in Between Existing Floor Joists

If you would prefer to lay a screed instead of using metal plates, this would involve yous in creating a sub floor.

The first task to undertake is to fix (normally nail) timber battens on either side of your flooring joists (in between each joist). Before yous fix the battens yous will have to measure the depth of the insulation and and then add a further 25mm onto this to ensure that you leave a 25mm gap between the top of the insulation lath and the tiptop of the joist in order to ensure that the underfloor heating water pipes and the screed, once laid, are and then affluent with the meridian of the joist and then that you tin so lay flooring boards over the top of this.

One time you lot have completed this chore you lot will then have ensure your flooring is suitably insulated by cut some dumbo, rigid insulation (for example Kingspan, Celotex etc…. check with your local edifice command department for the exact requirements) and then laying this on height of the timber battens you have previously fixed to either side of your joists and then that information technology fills the open void between each joist. You have to ensure the insulation is fixed tightly and that there are no gaps between it's edges and the joists that information technology sits between.

Once this has been achieved you volition so have to lay the heating pipework on pinnacle of the insulation boards and then clip the pipework to the boards using insulation clips.

With the pipework at present laid you can then go ahead and pour your screed over, ensuring that it is flat and level and flush to the top of the flooring joist. In one case the screed has dried and is solid you can then lay your chosen floor on top (usually chipboard first and and then for example laminate or tiles on top). Important Annotation: If yous choose the higher up option and you desire a natural wood flooring finish please ensure that the screed is 100% cured before you start laying and flooring

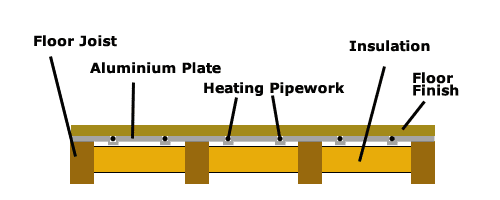

Heating Pipes Between Timber Joists Using Metal or Aluminium Plates

The get-go task is to insulate in between all the joists. For this you will demand either quilt insulation or board insulation. One time you have insulated you volition then have to decided whether yous want to use a metallic or aluminium plate.

Once yous have decided these are so fixed (normally nailed) to the joists. Notation: make sure that y'all exit at least a 200mm gap at either end of each pipe run and then that y'all then allow yourself enough room for the pipes to turn 180 degrees in to the next run.

The pipe piece of work then runs in the aluminium plates and when activated they heat the plates which in turn then heats the floor in an even spread across the entire flooring surface.

Water Underfloor Heating Pipework Laid in Timber Floor

Heating Laid on meridian Existing Timber Floor Using Metal or Aluminium Plates

Every bit this suggests, the heating sits on top of an existing timber floor. Similar to the in a higher place, the joists still need to be insulated in the aforementioned manner using either quilt or board insulation.

Underfloor Water Heating Aluminium Floor Plate

One time this has been washed you and then need to lay 20mm batts (timber) on superlative of the joists making sure that centres are at 400mm. In one case y'all have laid your battens on peak of the existing timber floor, as above, you and then accept to decide whether yous want to utilize a metal or an aluminium plate to lay your pipework in.

Once you lot have decided the plate is then laid and fixed to the battens and so the pipework is laid on to the plate.

Once more, in the above case the aforementioned heating principle applies, the pipework heats the plate and the plate then heats the floor in an fifty-fifty spread across the flooring surface

Source: https://www.diydoctor.org.uk/projects/unfloorwater.htm

Posted by: driverrurnins.blogspot.com

0 Response to "How To Install Water Underfloor Heating"

Post a Comment